AMPTHAI

TECHNOLOGY

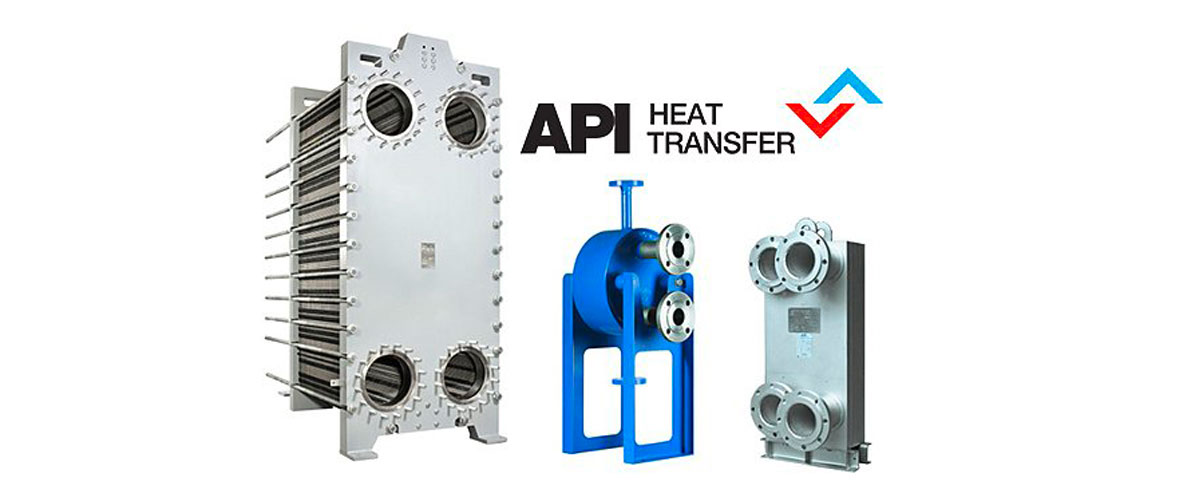

ตัวแทนจำหน่าย Ampco pumps และ API Scmidt-Bretten plate heat exchanger

About

บริษัท แอมปไทย เทคโนโลยี จำกัด เป็นตัวแทนจำหน่ายแห่งเดียวในประเทศไทยสำหรับ Ampco Pump จากอเมริกา และ Schmidt Plate Heat Exchanger รวมถึง Schmidt Thermal System และ Shell and Tube Heat Exchanger จาก เยอรมันเรามีประสบการณ์และความเชี่ยวชาญเกี่ยวกับปั๊มและเครื่องแลกเปลี่ยนความร้อนมามากกว่า 20 ปีพร้อมให้คำปรึกษาและบริการทั่วประเทศไทย

Ampthai Technology Co., Ltd. is the sole distributor in Thailand for Ampco Pump from United State and Schmidt Plate Heat Exchanger as well as Schmidt Thermal System and Shell and Tube Heat Exchanger from Germany. We have expertise in pumps and heat exchangers for over 20 years, with consulting and services throughout Thailand

Products

Contact Us

241/21 iField Bangna Village, Kanchanaphisek Road, Dokmai, Prawet, Bangkok 10250

02-1163855, 062-2965285